|

|

| Home :: Custom Injection Molding :: Tooling |

|

ToolingIPP realizes quality parts start with a well constructed tool. We have a full staff of design and tool engineers that work with your personal to get the details up front. This way we can avoid timely delays and costly repairs and modifications.

IPP builds tools in-house but also has the resources and connections to build tools abroad in order to meet your pricing and lead time needs. |

|

|

Unique Unit-Cavity Tool |

|

|

|

|

|

Allows for multiple part production using a single tool. Time sharing production reduces your part and tool cost. |

|

|

|

Unit-Cavity Tooling is a specialty of IPP for many years. This form of family molding can save customers significant sums of tooling and part prices by essentially sharing tool space and production time.

For more details on our unique unit-cavity tools, please call us. We’d be happy to offer you more details.

Our engineers can provide design assistance. Using Inventor’s 3-D solid modeling software, we can communicate with most widely used 3-D CAD software.

Secondary services include mechanical assembly, drilling, gluing, and more. |

|

|

|

|

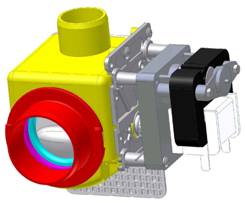

| 3-D solid model of a drain valve requiring several components including multiple injection molded parts, vendor sourced components, using pneumatic drills and fixtures during assembly. |

4 cavity mold which produces a 45-degree PVC fitting |

|

|

|

|

|

|

|

|